- Also called the Lost-wax casting, “investment casting”, “precision casting”, or cire perdue which has been adopted into English from the French is the process by which a duplicate metal sculpture (often silver, gold, brass or bronze) is cast from an original sculpture. Intricate works can be achieved by this method.

- A process used in metal casting that consists of making a wax model (as of a statuette), coating it with a refractory (as clay) to form a mold, heating until the wax melts and runs out of small holes left in the mold, and then pouring metal into the space left vacant. This technique is known as solid casting.

- A method of bronze casting using a clay core and a wax coating placed in a mould. The wax is melted in the mould and drained out, and bronze poured into the space left, producing a hollow bronze figure when the core is discarded.

- The weight and expense of solid casting prohibit its use for large works. This lead to the development of hollow casting.

- It was found that it was possible to take moulds from a glyptic work by suspending a core form with core pins in between the moulds and by filling the interspace between the mould and the core with molten metal and obtain a hollow cast.

- The other technique is to shape a core form slightly smaller than the cast intended in metal and applying wax sheets equal to the intended thickness of the cast over the core form.

- Metal-chasing then follows.Just as the wax model was finished, the casting is worked until the telltale signs of the casting process are removed, so that the casting now looks like the original model. Pits left by air bubbles in the casting and the stubs of the sprucing are filed down and polished.

The origin and progress are closely linked with the discovery and knowledge of the use of metal. Early man observed that metal possessed certain unique properties. He discovered that it was hard in natural state, ductile when heated, melted at a higher temperature and solidified when cooled . Again two or more metals could be combined to form an alloy which was even harder than the parent metals.

- Thus he developed the technique of forging and casting for his use. The development of clay moulding technique ushered the invention of cire perdue technique of casting. Man now desired to cast complicated forms. This required new techniques in modeling and moulding.

- He started Moulding in wax with the details of anatomy bespeaking not only the highest artistic excellence in the sculptor who could make such a fine study individually to perfection but also of his technical perfection in reproducing the finest details in an almost untouched cast image requiring little or no final finishing touches.

- The technique was used all over the sub-continent with an amalgam of metals ranging from five to eight in the solid or hollow method of casting as required by the size and purpose.

- Though, It is difficult to say when and where the technique was first invented. In India it is known to have been in use nearly five thousand years ago. Much has been said about the glory of the ancient Indian bronze cast by this process.

- It seems to have almost parallel developments in different areas of the old world.The technique is practiced in Nepal, Tibet, Ceylon, Burma, Thailand, Indo-china and Indonesia. The methods used in these countries have affinities to those found among our craftsmen and obviously seem to have reached these regions, along with the spread of Indian civilisation. The techniques used during the Shang period in ancient China and the traditional techniques found among the Japanese craftsmen are synonymous to our traditional techniques. Lost-wax casting was widespread in Europe until the 18th century, when a piece-moulding process came to predominate.

- The media and methods used in ancient civilizations of Egypt, Mesopotamia, Greece, Rome, Peru (Incas), African Kingdoms of Benin, Yorubaland by the craftsmen compare well with the existing techniques of India.

Today the traditional Indian craftsmen in this art are facing great economic distress due to dwindling of their traditional patrons. Dire poverty often drives some of them to take up other vocations of profit. This might result in the extinction of this traditional art. Such a situation prompted me to promote the art. Any positive result might go a long way in preserving our indigenous tradition.

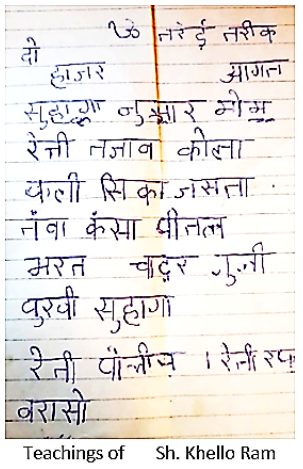

- During my stay in Dharamshala , Kangra, sometime in mid eighties; I came across Sh. Khello Ram, aKalaiwala (Kalaigar); asking for applying Kalai on utensils; still very common in Indian households. The word “Kalai” is derived from the Arabic language which means “white wash or tin”. The process of coating an alloy surface such as copper or brass by deposition of metal tin on it. I invited this community craftsman to my residence to work on the kitchen utensils of the household.

- His subsequent social visits revealed his talent of casting metal in to iconic statues (cire perdue technique) that aroused curiosity and woke up the artist in me. We started working together in my leisure hours. He was willing and supportive. I was impressed by his artistic traits. Later, he introduced me to his family; hailing from Bharmour, Chamba. Sometimes his wife also joined us to assist in the ‘heat process’, mainly the blowing of the bellows to make brisk fire from the bark of the pine tree(cheel ).

- In this method only one casting is possible because the mould is destroyed to release the cast. It has a drawback that of the danger of losing the labour of the artist, if casting is defective; hence the development of process of indirect cire perdue casting.

- Though some form of indirect process of cire perdue casting was prevalent among the craftsmen in some ancient civilizations , a systematic use of it or sculpture casting came into use, since the Renaissance age in Italy. With the advance of science and technology the plaster piece-mould was replaced by the flexible mould method, first by using gelatine and later with natural rubber and today with synthetic flexible moulding media. In the indirect process the original is generally in clay and a plaster copy of it is obtained through the waste mould process. A wax replica of the plaster copy is obtained for cire perdue casting with a plaster piece mould or by flexible mould. The indirect process enables the sculptor to guard himself against the danger of losing his original by conserving it in the negative form in the piece mould or flexible mould. It also permits him to have a number of copies of his creation.

For centuries man has been depending upon beeswax as the principal modelling medium for cire perdue casting. In a warm climate it turns too soft and in a cold climate it turns too hard for working. In order to make it suitable for working in different climatic conditions the craftsmen in many areas mix rosin, oil, wool fat, and prepare compounds according to their needs.

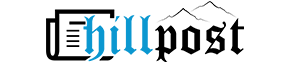

- I came across one Sh Durga Parsad of Teekam Garh,Madhya Pradesh, in an exhibition in Delhi ; who came out with one such recipe. Sh Khello Ram* used only mustered oil and that too to grease his palms.

Now a days industrial technology has produced the micro-crystalline wax which have been found to be more suitable for cire perdue casting. Micro-crystalline wax, a by-product of petroleum is marketed in forty different grades and can be used without the use of additives except for a colouring medium. Being an industrial by-product it is cheaper than beeswax.

I read in India Today of May, 2007 that the modeling clay from Mlelgaon, Jodhpur was the best.

………………………………………………………………………………………………………………………………………………………………….

With inputs from: Cire Perdue CASTING IN INDIA by M V KRISHNAN

*It is sad that Sh. Khello Ram passed away in 2016 and his wife also died two years after him as I came to know from their son Rajesh who lives in (Vill. Suted) Dharamshala.

Prof. (Er.) Chander P Mahajan is an art critic & a free lance journalist. The Environmentalist stays in Shimla and Dalhousie, Himachal Pradesh, India.

The origin and progress are closely linked with the discovery and knowledge of the use of metal. Early man observed that metal possessed certain unique properties. He discovered that it was hard in natural state, ductile when heated, melted at a higher temperature and solidified when cooled . Again two or more metals could be combined to form an alloy which was even harder than the parent metals.

The origin and progress are closely linked with the discovery and knowledge of the use of metal. Early man observed that metal possessed certain unique properties. He discovered that it was hard in natural state, ductile when heated, melted at a higher temperature and solidified when cooled . Again two or more metals could be combined to form an alloy which was even harder than the parent metals.

Today the traditional Indian craftsmen in this art are facing great economic distress due to dwindling of their traditional patrons. Dire poverty often drives some of them to take up other vocations of profit. This might result in the extinction of this traditional art. Such a situation prompted me to promote the art. Any positive result might go a long way in preserving our indigenous tradition.

Today the traditional Indian craftsmen in this art are facing great economic distress due to dwindling of their traditional patrons. Dire poverty often drives some of them to take up other vocations of profit. This might result in the extinction of this traditional art. Such a situation prompted me to promote the art. Any positive result might go a long way in preserving our indigenous tradition.

For centuries man has been depending upon beeswax as the principal modelling medium for cire perdue casting. In a warm climate it turns too soft and in a cold climate it turns too hard for working. In order to make it suitable for working in different climatic conditions the craftsmen in many areas mix rosin, oil, wool fat, and prepare compounds according to their needs.

For centuries man has been depending upon beeswax as the principal modelling medium for cire perdue casting. In a warm climate it turns too soft and in a cold climate it turns too hard for working. In order to make it suitable for working in different climatic conditions the craftsmen in many areas mix rosin, oil, wool fat, and prepare compounds according to their needs.